Railway

Years of experience support us with a very broad know-how in the sector, both at the level of rolling stock and infrastructure. We work with all kinds of special pieces and we adapt to each project and delivery needs on time and form. All the materials used comply with the European railway regulation EN 45545-2 and with quality standards.

Infrastructure

- Under rail seat plates

- Elastic rubber pads

- soles under sleeper

- Elastic chipboard pads

- Cups for concrete blocks

- Elastomer under floating slab

Under rail seat plates

It is the transition element between the rail and the sleeper, in charge of reducing the dynamic effects of the rail towards the sleeper, by damping the impacts in the downward vertical direction and the loads and vibrations induced by the passing of the trains.

Depending on the characteristics of the rubber used in the injection process of these pieces, the different elasticities required by the railway administrations are obtained and can range between 60 kN/mm and >300 kN/mm; depending on the level of noise and vibration attenuation to be achieved.

They also provide electrical insulation for both rails and help prevent the rail from sliding longitudinally.

Under-rail seat plates are elements that work outdoors and that, in addition to environmental aggressions, characteristic of the place where they are installed, are, and due to the passage of trains, permanently supporting static and dynamic stresses.

To ensure the good quality of products installed on railway networks, there are a series of European standards that indicate the demanding tests that they must pass.

The parts injected by Junta3 meet the European standards applied to under-rail seat plates.

Elastic rubber pads

They are elements that are part of high-performance fastening systems for the railway, whose main mission is to provide great attenuation of noise and vibrations, caused by the passage of trains on the rails, and which are transmitted to nearby buildings. to railway facilities.

Due to the way in which these parts work and the need to achieve high elastic behavior that lasts over time, the most used raw material is natural rubber, to which agents are added, which reinforce its behavior in the face of environmental aggressions (shocks climatic, UV rays, etc.) characteristics of the places where they are installed.

To ensure the good quality of products installed on railway networks, there are a series of European standards that indicate the demanding tests that they must pass.

The parts injected by Junta3 meet the European standards applied to this type of product.

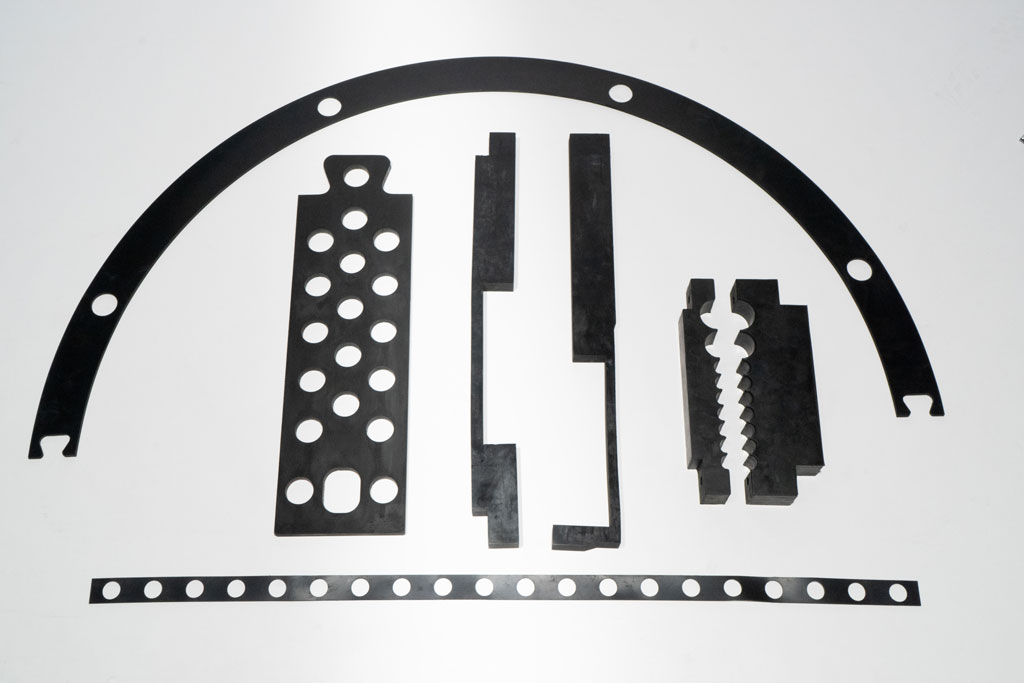

soles under sleeper

They are elements that are integrated, thanks to their design, in the lower part of the railway sleepers, at the time of their manufacture.

The main objective is to minimize the crumbling of the ballast and the concrete of the sleepers, in addition to providing the system with a reduction in noise and vibrations.

The direct contact of the ballast with the concrete produces a constant deterioration of the sleeper. The use of soles under the sleeper reduces this erosion of the aggregates of the sleeper, since it increases the contact surface of the sleeper with the ballast stones, on which it rests.

Its use reduces maintenance costs, characteristic of a railway track on ballast.

To ensure the good quality of products installed on railway networks, there are a series of European standards that indicate the demanding tests that they must pass.

The parts injected by Junta3, in natural rubber, meet the European standards applied to this type of product.

Elastic chipboard pads

They are elements that are located at the base of the cups and on which the concrete blocks rest and where they act as an element for absorbing vibrations.

They are made of vulcanized rubber from recycled truck wheels, which is bonded by using a binder (usually isocyanates or polyurethanes) and a production process in which heat and pressure are applied for a certain time. .

To ensure the good quality of products installed on railway networks, there are a series of European standards that indicate the demanding tests that they must pass.

The pieces manufactured by Junta3 meet the European standards applied to this type of product.

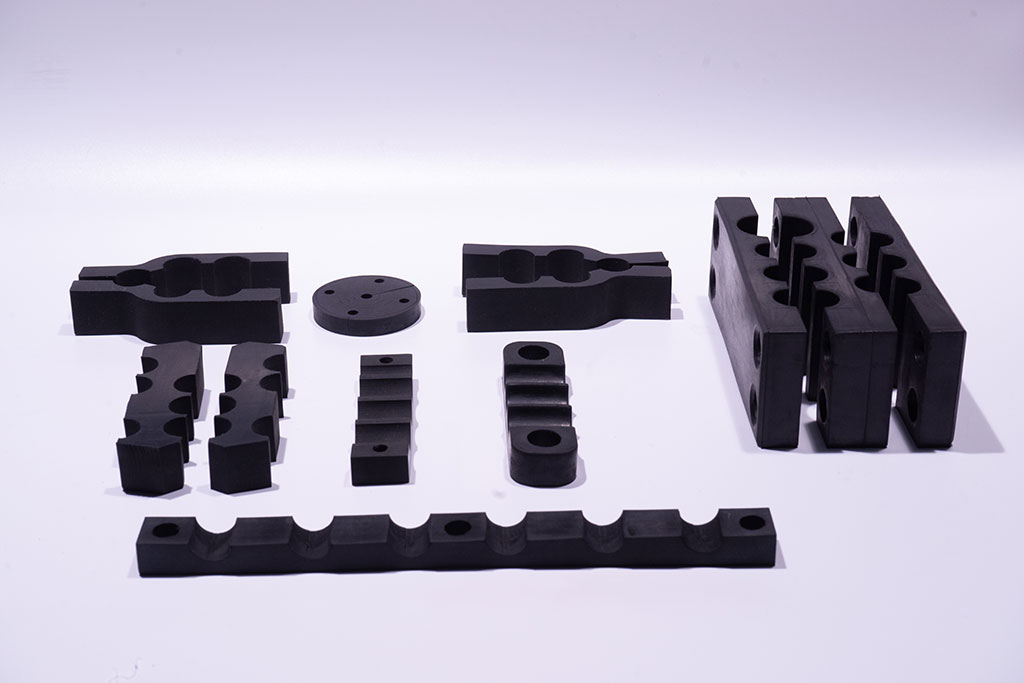

Cups for concrete blocks

They are elements that are part of fastening systems for the railway, whose main mission is to house the concrete blocks and, together with the elastic rubber or chipboard pads mounted inside these cups, reduce the vibrations caused by movement. passage of trains on the rails, and which are transmitted to the buildings near the railway facilities.

Due to the way these pieces work, the need to allow the replacement of the concrete block, in case of breakage, and to support the movements of said block when passing trains. The commonly used material is EPDM rubber.

Elastomer under floating slab

They are elements that are part of high-performance fastening systems for the railway, whose main mission is to provide great attenuation of noise and vibrations, caused by the passage of trains on the rails, and which are transmitted to nearby buildings. to railway facilities.

Due to the way these pieces work and the need to achieve a specific elastic behaviour, under the weight of the concrete slab and the rest of the components of this “mass-spring” attenuation system, the most used raw material is EPDM. .

Junta3 manufactures this elastomer, which acts as a "spring" in the aforementioned system.

To ensure the good quality of products installed on railway networks, there are a series of European standards that indicate the demanding tests that they must pass.

The parts injected by Junta3 meet the European standards applied to this type of product.

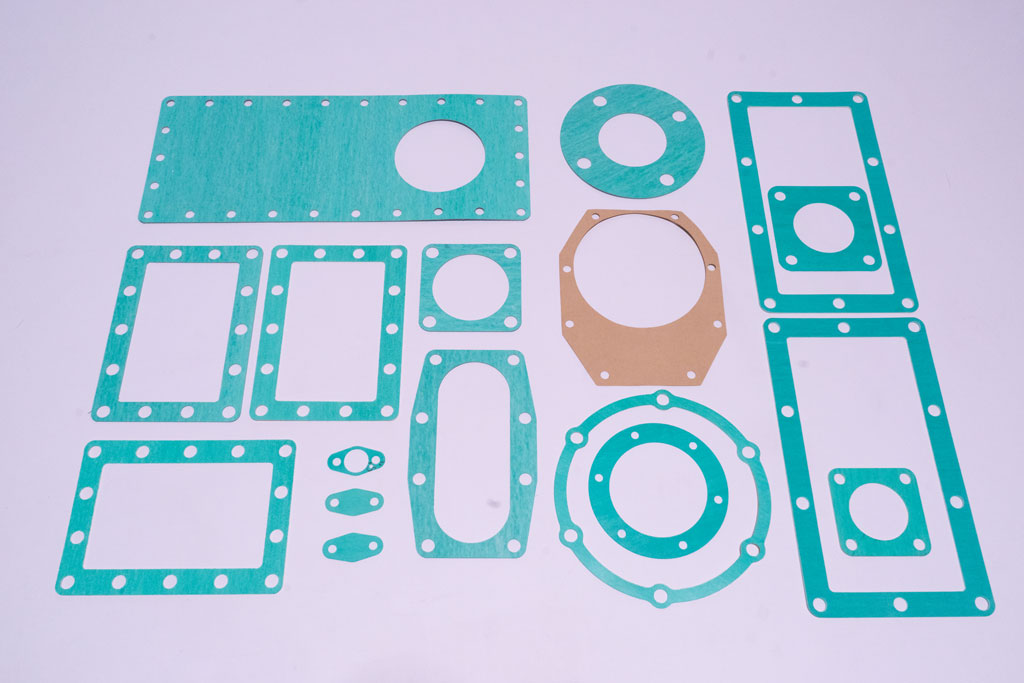

Rolling material:

Custom pieces of various types of rubber:

- sponge rubbers

- compact rubbers

Possibility of manufacturing the pieces with or without adhesive.

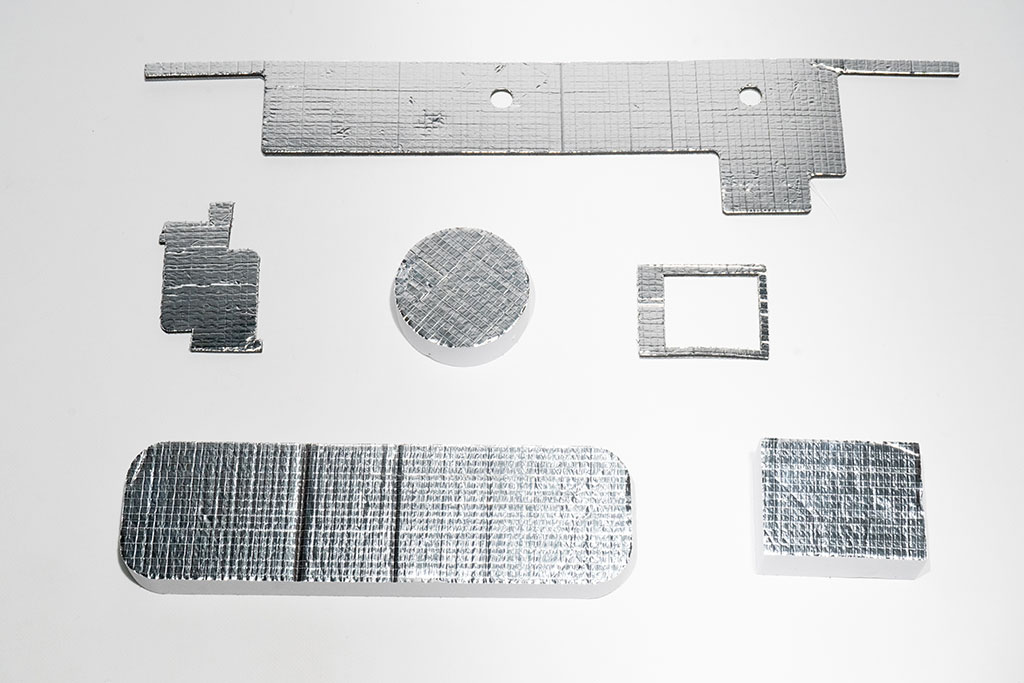

Isolations:

We take care of the design and cutting of the insulating material inside the structure of the different cars.

Reworked profiles:

We use various materials such as:

- Compact and spongy rubbers

- Compact and spongy silicones

All our products comply with the EN 45545 standard